Add to Cart

Zeolite Rotor Concentrator

(1) organic waste concentrated wheel. For separating the solvent from the exhaust gas containing organic solvent is widely used in paint waste gas pre-treatment, the organic solvent recovered from the exhaust gas containing high-boiling organic solvent and the solvent containing the odor control plant

(2) concentrated ammonia runner. Treatment of waste gas containing low concentrations of ammonia, ammonia utilization achieved

(3) hydrogen sulfide concentrate runner. For the treatment of organic fertilizer foul odor produced by fermentation and drying process. The company can concentrate rotor according to the user's need to develop a variety of purposes sieve

Working principle of molecular sieve concentrated runner

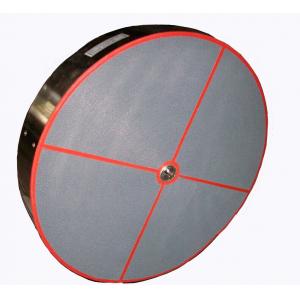

Runner honeycomb structure, see on Figure 2. Runner adsorbent material can be adsorbed hydrophobic organic solvent molecular sieves . Wheel is divided into three regions namely treatment area , the cooling zone and regeneration zone , in a motor driven wheel rotation, rotation speed of 1-12 rev / hour

Solvent -containing gas into a relatively clean air flow from the area after the treatment , the organic solvent content can be reduced to a minimum the following 50mg/m3 , meet the national environmental emissions requirements. Part of the air contained in the organic solvent from the regenerative effect of the fan after the stream cooling zone is heated to the regeneration heater 180 ℃, then through the regeneration zone of the rotor . When the regeneration air flows through the rotor , the rotor of the adsorbed organic solvent is desorbed at high temperature , while the regeneration air is taken away . When turning work , the regeneration air and process air ratio is between 1 / 3 to 1 / 10 , the regeneration of the organic solvent

Contact Information

E-mail: sales @ hodreamtechrotor.com

hodream @ vip.163.com

QQ: 2412108818

Skype: beisudakeling

WeChat: hodreamgroup

Tel: +86-755-2998 5896

MP: +86-134 2388 9933

Http: //www.hodreamtechrotor.com

Please do not hesitate to contact us if you need any help!